Understanding Cleanroom ISO Classifications: Cleanroom Principles and Key Considerations for Selecting Cleanroom Consumables

In industries ranging from food technology and biomedical engineering to precision electronics and high-tech manufacturing like semiconductors, cleanrooms serve as critical facilities for controlling product quality. Newtech Technology introduces the principles of cleanrooms and ISO classification standards across various sectors, while highlighting the importance of cleanroom consumables. This enables your enterprise to gain early understanding and deploy clean environments effectively.

What is a Cleanroom?

A cleanroom is an environment with highly controlled contamination levels, ensuring dust particles within the space are effectively maintained within specific standards. It is specifically designed for industries requiring contamination-free environments, such as semiconductor manufacturing. Beyond eliminating various contamination sources, cleanrooms also require precise control over multiple environmental parameters including temperature, humidity, airflow velocity, indoor pressure, noise, vibration, and lighting.

How are cleanroom grades classified? Detailed explanation of the international standard ISO 14644-1

Cleanroom grades are defined by the international standard ISO 14644-1 as a measure of air cleanliness within the cleanroom. This classification is based on the maximum allowable number of airborne particles per cubic meter (1m³) of air that are greater than or equal to a specific particle size. Simply put, the lower the ISO cleanroom grade number, the fewer particles are permitted, indicating a cleaner environment.

Cleanroom ISO Classification Table

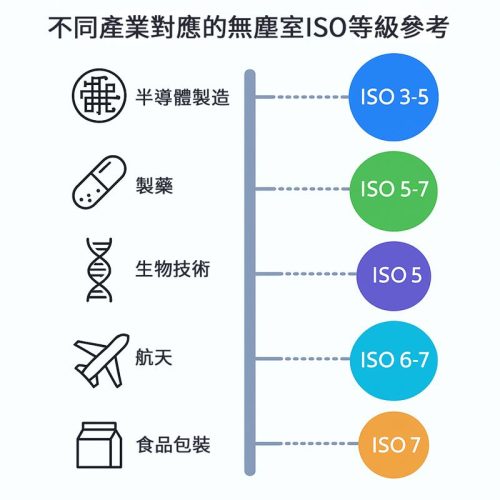

Cleanroom ISO grades range from ISO 1 to ISO 9, comprising nine levels, with ISO 9 being the lowest and ISO 1 the highest. As shown in the table below, each increase in ISO grade represents approximately a tenfold stricter control over particle counts. A lower ISO number indicates higher cleanliness requirements and fewer permitted particles. Different industries select appropriate cleanroom grades based on product specifications. For instance, semiconductor manufacturing typically uses ISO 3 to 5 grade cleanrooms, while food and pharmaceutical industries often adopt ISO 7 to 8 grades as standards.

| ISO Classification | Maximum concentration of particulate matter per cubic meter (1m³) of air | |||||

|---|---|---|---|---|---|---|

| particle size | ≥0.1μm | ≥0.2μm | ≥0.3μm | ≥0.5μm | ≥1μm | ≥5.0μm |

| ISO 1 | 10 | 2 | - | - | - | - |

| ISO 2 | 100 | 24 | 10 | 4 | - | - |

| ISO 3 | 1,000 | 237 | 102 | 35 | 8 | - |

| ISO 4 | 10,000 | 2,370 | 1,020 | 352 | 83 | - |

| ISO 5 | 100,000 | 23,700 | 10,200 | 3,520 | 832 | 29 |

| ISO 6 | 1,000,000 | 237,000 | 102,000 | 35,200 | 8,320 | 293 |

| ISO 7 | - | - | - | 352,000 | 832,000 | 29,300 |

| ISO 8 | - | - | - | 35,200,000 | 8,320,000 | 293,000 |

ISO Cleanroom Grade Reference for Different Industries

| Industrial Applications | Corresponding ISO grade | Application Examples |

|---|---|---|

| Extreme Nanoscale Manufacturing | ISO 2 | |

| Advanced EUV Lithography Systems, Quantum Computing Component Manufacturing Advanced EUV Lithography Systems, Quantum Computing Component Manufacturing | ISO 3 | Extreme Ultraviolet Optical Lens Manufacturing, Atomic Layer Deposition (ALD) |

| Advanced semiconductor manufacturing processes | ISO 4 | Logic Process FinFET, DRAM/3D NAND Front-End Process |

| Semiconductor fab | ISO 5-6 | Wafer exposure and etching processes |

| Semiconductor Packaging | ISO 6-7 | Testing, Assembly, Packaging |

| Photovoltaic Panel | ISO 6-7 | OLED/LCD Packaging Production Line |

| Biomedical | ISO 7-8 | Medical device assembly, pharmaceutical manufacturing |

| Food Biotechnology | ISO 7-8 | Sterile Food Production Line |

Comparison of ISO Cleanroom Standards with Other Regional Standards

In addition to the internationally recognized ISO 14644-1 cleanroom standard, certain industries may utilize alternative specifications:

- FED-STD-209E (U.S. Standard): An airborne particulate cleanliness standard issued by the U.S. federal government in 1992. Although formally superseded by ISO standards in 2001, it remains in use by some American companies—particularly within the semiconductor industry—which continue to employ classifications such as Class 1, Class 10, and Class 100.

- JIS B9920 (Japanese Standard): Japan’s national standard developed based on ISO 14644. Its content is fully consistent with the ISO standard but aligns more closely with Japanese industrial practices in application details.

- VDI 2083 (German Standard): A common cleanroom technology standard in European manufacturing, established by the Association of German Engineers (Verein Deutscher Ingenieure). Beyond air cleanliness classification, it also covers overall cleanroom design and operational management.

The four cleanroom classification standards are mutually comparable. The following table provides a classification correspondence:

| ISO 14644-1 Class | FED-STD-209E Class | JIS B9920 (Class) | VDI 2083 Class |

|---|---|---|---|

| ISO 1 | - | 1 | 1 |

| ISO 2 | - | 2 | 2 |

| ISO 3 | 1 | 3 | 3 |

| ISO 4 | 10 | 4 | 4 |

| ISO 5 | 1000 | 5 | 5 |

| ISO 6 | 10000 | 6 | 6 |

| ISO 7 | 100000 | 7 | 7 |

| ISO 8 | - | 8 | 8 |

| ISO 9 | - | 9 | 9 |

Core Principle of Cleanrooms: Airflow and Filter Control

The principle of a cleanroom involves controlling and filtering airborne particles to maintain indoor air cleanliness, thereby preventing contaminants from affecting product quality or experimental integrity.

1. Air Filtration System

The air filtration system is the most critical component in cleanroom principles. It employs a multi-stage filtration method utilizing three mechanisms—interception, inertia, and diffusion—to capture particles of varying sizes:

- The interception mechanism targets larger particles, directly trapping dust, pollen, and other coarse particles using filter media fibers or mesh structures.

- The inertial mechanism captures heavier particles. When these particles move at high speeds within the airflow, they collide with filter fibers due to inertia and become trapped.

- The diffusion mechanism specifically handles extremely small particles like smoke and oil mist. These particles undergo Brownian motion (random movement within a fluid), creating irregular paths that increase their chances of colliding with filter fibers.

External air first passes through a primary filter to capture large particles, then undergoes further purification through a medium-efficiency filter, and finally passes through a high-efficiency filter (HEPA or ULPA) to remove fine particles, bacteria, and viruses, ensuring the air supplied to the work area meets specified cleanliness standards.

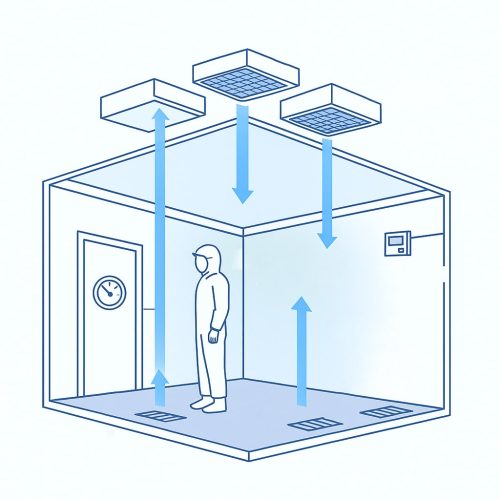

2. Airflow Control and Distribution Systems

Airflow control within cleanrooms is also critical for maintaining cleanliness levels. Depending on specific cleanliness requirements, cleanrooms can be designed with different airflow control principles:

- Unidirectional Air Flow provides a single-direction airflow, where clean air is blown vertically downward from the ceiling and returned through floor vents. This is suitable for environments demanding high cleanliness.

- Turbulent Flow allows air to circulate randomly within the space, suitable for environments with lower cleanliness requirements and relatively lower costs.

Airflow systems can also be categorized into three types:

- Pressurized Static Box System: Air is pumped into a static box and then pushed through filters into the cleanroom.

- Ducted Supply and Ducted Return System: Air is transported into and out of the cleanroom via ductwork.

- Ducted Supply and Open Return System: Air is delivered through ducts and naturally flows into an open return system, representing the most cost-effective option.

3. Pressure Control and Sealing Technology

Through precise pressure control principles, cleanrooms effectively prevent cross-contamination of pollutants by maintaining appropriate positive or negative pressure environments. Positive-pressure cleanrooms continuously pump in clean, filtered air; when doors or windows open, air flows outward, preventing external contaminated air from infiltrating. This is suitable for protecting sensitive products like microchip manufacturing. Negative pressure cleanrooms are used to prevent internal contaminants from escaping, making them suitable for environments handling hazardous substances.

The pressure control system incorporates a dedicated air handling unit equipped with HEPA filters to supply filtered, conditioned air. It maintains the required pressure differential by regulating the volume of air supplied and exhausted. The system demands strict airtightness control, including seals for doors, windows, and ductwork, and is fitted with a pressure monitoring system to continuously track pressure differential changes.

4. Environmental Parameter Monitoring System

Cleanrooms also feature advanced real-time monitoring systems that continuously track and regulate multiple critical environmental parameters. These systems integrate particle counters, sensors, and software networks to provide continuous monitoring, alarms, and feedback functions. Monitored parameters include particle counts, temperature and humidity, pressure differentials, airflow velocity, carbon dioxide concentration, bioactive particles, and oxygen concentration. The system delivers real-time alerts, immediately notifying management when data exceeds normal ranges to ensure the cleanroom environment consistently maintains specified standards.

Classification and Importance of Cleanroom Consumables

Beyond the hardware of the aforementioned systems, consumables are also essential for maintaining the cleanroom’s dust-free environment at the required cleanliness level. These include:

Air Filtration System Consumables

The air filtration system is the core of a cleanroom. The filtration system fan must be used in conjunction with air filters, which are the most critical consumables in a cleanroom. They must be replaced regularly to ensure compliance with the air cleanliness requirements of the ISO 14644-1 standard for cleanrooms.

Pre-filter: Classified as a primary filter, it protects more expensive HEPA filters from clogging. It is recommended to replace it 6 times per year or every 2 months.

Bag Filter: Classified as a medium-efficiency filter, it is typically replaced once per year.

HEPA Filters (High-Efficiency Particulate Air Filters): As high-efficiency filters, standard HEPA filters must remove 99.97% of particles 0.3 μm or larger. Replacement frequency varies by operating environment. The industry standard is every 3 years, but with adequate pre-filter protection, replacement can extend to every 4 to 6 years. With regular integrity testing, maximum lifespan can reach 8 years. However, in highly contaminated environments (e.g., ISO Class 8 cleanrooms), annual replacement may be necessary.

ULPA Filters (Ultra Low Penetration Air Filters): Outperform HEPA by capturing over 99.999% of particles. When protected from damage and excessive use, ULPA filters should be replaced every 4 to 6 years.

Cleaning Supplies

Cleaning consumables are essential for maintaining daily cleanliness in cleanrooms, removing surface contaminants and preventing cross-contamination. These supplies must be specially designed to avoid shedding fibers or particles while effectively removing various types of pollutants.

Cleanroom-approved disinfectants: Used for routine surface wiping, should be applied weekly to prevent residue buildup.

Cleanroom Wipes and Cleaning Cloths: Low-lint, sterile wipes for daily cleaning of surfaces, equipment, and workbenches. Key cleanroom consumables include polyester fiber wipes (lint-free, high absorbency), microfiber wipes (removes fine particles), and pre-moistened wipes (pre-saturated with cleaning solution).

Adhesive Mats: Placed at cleanroom entrances to capture particles from footwear. Should be replaced monthly or as needed based on contamination levels.

Personal Protective Equipment

Personal protective equipment serves as the first line of defense against human contamination while shielding operators from harmful substances. It is one of the essential consumables in cleanrooms that requires regular replacement.

- Cleanroom garments: Including coveralls, hoods, shoe covers, and gloves. Replacement frequency depends on cleanroom classification and usage intensity.

- Hair nets and beard nets: Single-use items that prevent hair or minute bodily particles from contaminating the air. Must be replaced each time the cleanroom is entered.

- Respirators: Prevent particles exhaled by personnel inside the cleanroom from entering the air.

Newtech Technology—Industry-Leading Provider of Professional Cleanroom Products and Services

The above outlines the principles, ISO classification standards, and applications of cleanrooms. Newtech provides consulting, design, and construction services for high ISO-grade cleanrooms, delivering comprehensive solutions to businesses with top-tier cleanroom products and systems. From high-quality cleanroom panel walls and ceiling systems to advanced HEPA filters and other consumables, we ensure every detail meets stringent cleanroom standards.

Newtech’s professional engineering teams tailor optimal cleanroom solutions for businesses, enhancing product quality and production efficiency. We also provide expert technical support to keep your cleanroom environment operating at peak performance. Contact us to explore customized cleanroom solutions.

References:

International Organization for Standardization – ISO 14644-1:2015 Cleanrooms and associated controlled environments Part 1: Classification of air cleanliness by particle concentration

ASHRAE Standard 170: Ventilation of Health Care Facilities

ashrae.org/technical-resources/standards-and-guidelines/standards-addenda/ansi-ashrae-ashe-standard-170-2017-ventilation-of-health-care-facilities

IEST – Federal Standard 209E Cancellation

Liberty Industries – HEPA vs. ULPA Filters